How Waterjet Cutting Works

Have you ever wondered how artistic iron designs are cut, shaped and designed? There are a wealth of tools and methods applied to achieve the desired result in metalworking, from hand-bending iron bars to precise cutting of patterns which are then welded together. One of the most interesting tools at the artisan’s disposal is the waterjet cutter. This device uses the most abundant resource on the planet—water—to cut through iron and steel! Learn about waterjets, how waterjet cutting works and how it can be applied to custom handcrafted iron projects for your home or work.

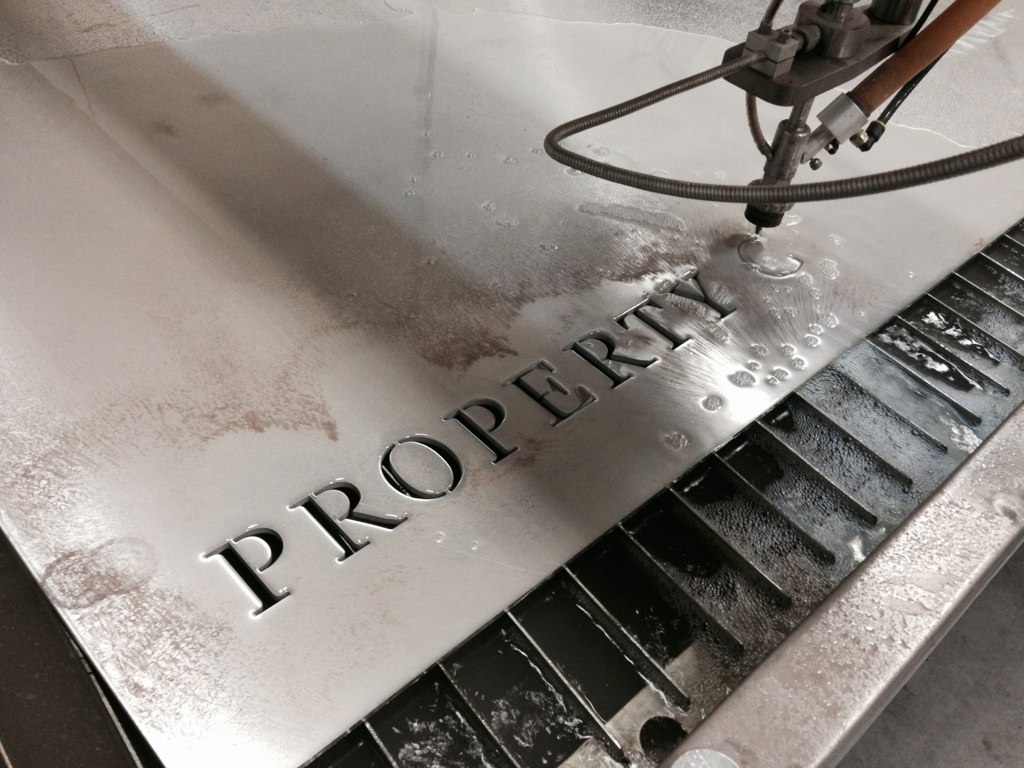

What Is Waterjet Cutting?

Waterjet cutting makes use of a tool called a waterjet that uses a high-pressure stream of water to cut through metal in precise shapes. Have you ever been to a DIY car wash and used the pressure washing wand? Waterjets are kind of like that, except they are far more focused and issue about 30 times as much pressure.

From Mining to Cutting

Waterjets were first invented in the mid-19th century for purposes of mining gold. They were used to cut through rock walls to expose the veins of gold beneath. By the 1980s they were being used as abrasives to remove grime and particulates from surfaces. It’s only within the past decade or so that the technology has advanced to the point where it’s small and focused enough to make precise cuts in metal.

Constant Pressure

Through the use of a waterjet, water is formed into a slicing tool, a literal blade that cuts through most surfaces. The water is focused through a jeweled opening, or nozzle at the end of a tube and wand; the opening is .015” or less in diameter. This focus creates extremely high pressure that sees the water erupt from the nozzle at anywhere from 900 miles an hour to nearly mach 3! This results in pressure of up to 55,000 PSI and forms the water into a blade-like shape which can never dull or overheat.

What It Can Cut

Waterjets can cut anywhere from two- to five-thousandths of an inch through up to four inches thick of iron, steel, granite, marble, stone, wood, plastic or a variety of other materials. Even better, the cut is so precise that it requires little to no finishing work. It’s exceptionally efficient, fast and precise. It can even go through titanium at a rate of 7 inches in a minute. The waterjet is another example of how technology has made the work of artisans and craftsmen faster and more efficient than ever. This tool has become invaluable to artists of all stripes and the technology will only continue to improve. It has certainly revitalized the iron working industry. If you would like to explore the benefits of this technology for your artwork, furnishing or even security purposes, why not spend some time looking at the services we provide? Get in touch with us today for more information or to place your order!